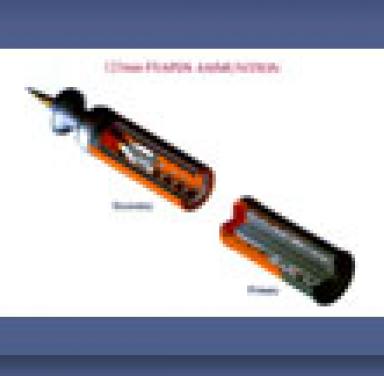

FSAPDS Ammunition

125 mm FSAPDS (SOFT CORE) AMMUNITION

Technology for development of Fin Stabilized Armour Piercing Discarding Sabot (FSAPDS) ammunition has been developed in the country by undertaking ab initio R&D activities in DRDO. Acquisition of this technology led to substantial enhancement of the fire power of in-service main battle tanks as well as those under development. The technology was extended to enhancing fire power of T-72 M1 tanks as well. The 125 mm FSAPDS ammunition on acceptance for introduction in services by the Army has been productionised successfully by Ordnance Factory Board. About 75,000 rounds of the state- of-the-art ammunition have been produced and production will continue at a rate of 40,000 rounds peryear, saving annual foreign exchange of Rs 200 crores per year

Fin Stabilized Armour Piercing Discarding Sabot (FSAPDS) ammunition is the most lethal kinetic energy ammunition, capable of destroying all known tank armour up to direct shooting range. The 125 mm FSAPDS (soft core) ammunition has been successfully designed and developed for enhancing the fire power of existing T-72 tank.

Design Aspects

The FSAPDS ammunition has been designed as a two-piece separate loading ammunition, capable of:

- Being fired from smooth bore T-72 tank gun

- Stowage in tank within the existing space

- Loading by auto-loader without affecting the rate of fire

- Ballistic performance to conform to the existing T-72 sight graticule pattern

- Defeating all NATO targets at a range of 2500

The complete round consists of two cartridges, an FSAPDS shot with a supplementary charge attached to it, called the secondary charge (or the front cartridge) and a main powder charge called the primary charge (or the rear cartridge). The secondary charge consists of a shot which includes the tungsten alloy penetrator, three-segmented aluminium sabots, a tail fin for stability in flight, nylon bands, rubber seal, a tracer and a combustible cylinder with propellant charge. The primary charge consists of a combustible cylinder with propellant charge, a steel cup which functions as the obturator and an electromechanical primer screwed on to the steel cup base.

Functioning of FSAPDS

The combination of HE, HEAT and FSAPDS ammunition, as per the requirement, can be stowed in the tank bins and loaded into the barrel by an auotmatic loading mechanism. When the round is loaded and fired from T-72 tank, the shot exits the muzzle and gases and aerodynamic forces acting on the sabot segments cause it to separate from the sub-projectile. The fin stabilised sub-projectile will continue to fly on its extremely flat trajectory to the target. Flight of the sub-projectile can be observed with the help of burning tracer.

Technology Involved

Manufacturing Technology FSAPDS components are sensitive and sophisticated in nature and demand utmost care during their manufacturing and assembly. The dimensional and weight accuracies in various components are maintained to very close tolerance limits to achieve optimal overall performance of the ammunition.

Great care has been taken in selecting the operation layout for various components and other manufacturing facilities to minimise the rejection rate. Because of the intricate design and the need for close tolerance limits, major components are manufactured in combination with NC/CNC, high productive semiautomatic machines.

By introducing NC/CNC machines in flexible manufacturing system (FMS) mode, provision has also been made for machining operation of components for other calibre FSAPDS ammunition. Automatic online inspection of components has been introduced stagewise to ensure quality control and to increase productivity.

Powder Metallurgy

The technology know-how developed on laboratory scale for the manufacture of high strength, high density tungsten alloy rods was converted into mass production methods and production established at HAPP. The heavy alloy rods are made from constituent powders through sintering process. The homogeneity and density along the entire length of the rod is maintained through in-built monitoring devices on the heating furnaces and online inspection at different stages.

Performance

- Accuracy < 0.3 miles

- Penetration Can defeat all NATO targets at a range of 2500m and beyond

- Range Effective lethal range up to 3000m

- Behaviour Functions satisfactorily at extreme climatic conditions

Surface Coating

Two critical aluminium components are exposed to very high temperature zones during launch. To withstand the environment, hard anodizing at sub-zero temperature as a surface protective coating was established for this purpose for the first time in Ordnance Factories. This also enhances the shelf life of the ammunition against corrosion.

Ultrasonic Flaw Detection Techniques for High Density Materials

Since the tungsten alloy manufactured by sintering method has density more than 17 g/cc, the flaw detection becomes critical. No suitable ultrasonic equipment for detecting the flaw below 0.8 mm crack size was available in the country. It was imported as a tailor-made equipment and successfully commissioned at HAPP. This unique non-destructive testing method gives reliability on mass scale for getting the penetrators tested.

Establishment of Polymer Materials

The technology for two critical components made out of Nylon 6/6 and silicon rubber were established with stringent specifications. These are critical items for enhancing the performance of the ammunition.

Semi-Combustible Cartrige Case

This technology, developed on pilot scale, was successfully transfered to the trade for meeting the bulk requirement of the Army.

Testing and Evaluation

The testing and evaluation facilities used during design, development and production stages have been augmented by high speed cameras, tracking radars and other critical instruments to suit the bulk production requirements.

Technology Transfer

The transfer of technology of this ammunition has been completed in record time and production agencies have been geared up to produce more than 40000 rounds per annum with high reliability of the ammunition. This product, engineered to stringent production and quality assurance specifications, has enhanced Army's self-reliance and fighting capability. Moreover, the country could save precious foreign exchange to the tune of around Rs 200 crores per annum.

125 mm FSAPDS ammunition developed by DRDO has enhanced Army's self-reliance and could save the country foreign exchange of around Rs 20 million per annum.